What We Do?

QS Metrology is a respected Professional Solution provider in the field of advanced quality inspection and material testing. Partnering and collaborating with some of the world’s leading Dimensional Metrology and Material Testing equipment manufacturers, we have been striving to bring the latest technology , depth of their expertise, and knowledge to India.

Product Verticals

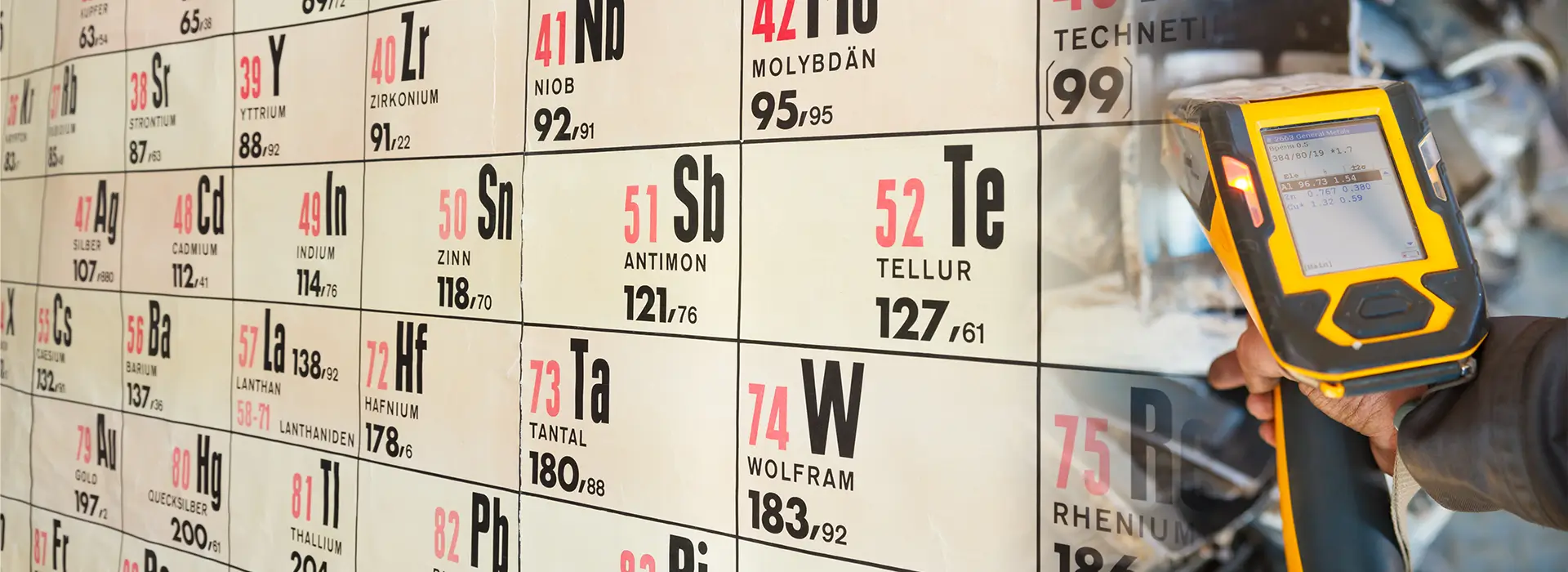

Elemental Analysis Solutions

Elemental analysis is a process where material samples like metals, minerals, soil, chemical compounds etc are analyzed for its composition. It can be...

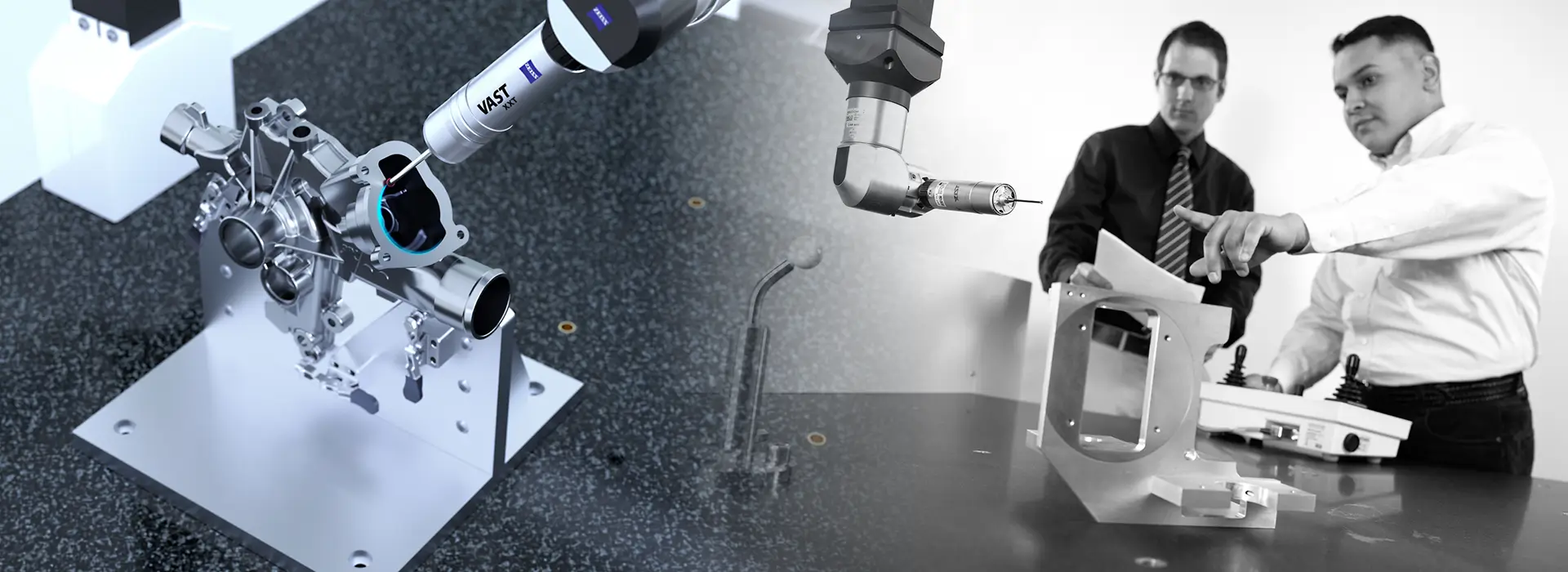

Industrial Quality Solutions

QS Metrology is a business partner for Carl Zeiss for their IQC division. We bring you a range of products like Surface Roughness Testers, Contour Testers, Roundness...

Imaging Solutions

We are a leading solution provider for Microscope based Imaging requirements in Automotive sector, Foundries, Forging industry and Research and Educational...

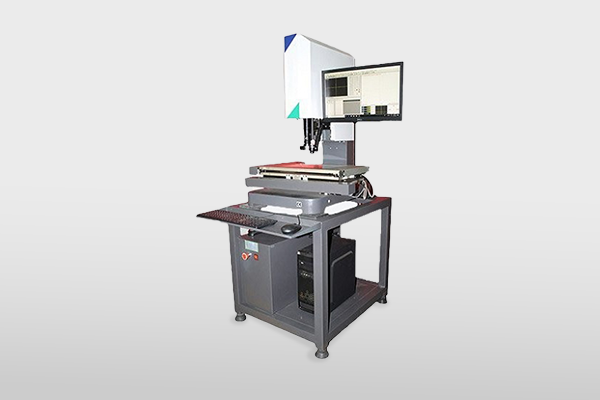

Video Measuring Machine

We offer a range of models in Video Measuring Systems – manual and CNC models with 2D/3D options and different table sizes. You can choose the right...

Coating Thickness Gages

From the world leader PHYNIX, Germany, QS Metrology brings you a wide range of world class coating thickness gauges that meets the different measurement...

In-line Inspection Systems

A machine vision system (MVS) is a type of technology that enables a computing device to inspect, evaluate and identify still or moving images. These systems...

Precision Metrology Solutions Across India

We proudly serve industries across major manufacturing and industrial hubs in India. Our expert team ensures timely support, installation, calibration, and after-sales service wherever you operate.

Our Mostly Serve Locations

What Sets QS Metrology Apart?

Strategic Partnerships with Global Industry Leaders

KBE can automate routine design tasks, reduce design cycle times, and improve design efficiency. By automating design processes, engineers can focus on more complex design tasks, which can lead to better design outcomes.

Decades of Industry Experience

With over a quarter-century of experience, QS Metrology’s legacy is built on deep technical understanding, trusted service, and a steadfast commitment to advancing Indian industry. The company has consistently delivered solutions that drive better outcomes and foster continuous improvement.

Precision Redefined for Modern Challenges

QS Metrology’s technologies are designed to meet the ever-evolving demands of next-generation ultra-precision measurements, particularly in fields such as optics, bearings, space, defence, aerospace, automotive, medical, metals and minerals, cements, and renewable energy. By shaping the winds of change, QS Metrology helps clients stay ahead in competitive markets.

Transforming Industry with Technology and Agility

The industrial landscape is undergoing rapid transformation, driven by trends such as Industry 4.0, the Internet of Things (IoT), and the shift to e-mobility. These changes, coupled with the growing shortage of skilled workers, require innovative solutions that are easy to use and adaptable to new measurement tasks and locations. QS Metrology’s focus on usability and efficiency enables its clients to thrive in this dynamic environment.

Exceptional, Committed Team

QS Metrology’s team of experienced engineers is its greatest asset. Their expertise ensures clients receive the highest quality advice on selecting the right models and machines for their applications. The company emphasizes minimizing downtime, providing responsive support, and fostering long-term relationships.

Speed and Agility in Service

Structured for swift decision-making, QS Metrology’s engineers are empowered to address customer needs directly, without unnecessary bureaucratic delays. The firm is committed to responding to customer issues within 48 hours on business days, ensuring that operations remain efficient and interruptions are minimized.

Industries We Serve

Automotive

Medical Device & Pharmaceutical

Aerospace

Electronic & Electric Component

Chemicals & Petrochemicals

Metal Foundries & Casting

Energy, Power & Renewables

Mining & Minerals

Looking for a Custom Measurement Solution?

Key Customers

Latest Blog

In today’s fast-paced manufacturing and metal fabrication industries, quality control is no longer just a final checkpoint—it is an ongoing process that …

In today’s precision-driven manufacturing world, quality control isn’t just a checkpoint — it’s the foundation of every successful production process. Companies in …

In industries where surface protection, durability, and quality control are critical, accurate coating measurement plays a vital role. Whether it is paint, …